Panasonic’s reputation for PLC and touchscreen technology within the Original Equipment Manufacturer (OEM) market is unparalleled. With their extensive selection of products plus their unbeaten THREE YEAR HARDWARE WARRANTY, touchscreens and PLC units from Panasonic are the first choice for equipment builders around the world.

FP0R series PLCs

The workhorse automation and control solution for many OEMs is Panasonic’s FP0R series of programmable controllers.

The FP0R is a high performance industrial machine controller, not a bare-minimum control option. FP0R PLCs offer ultra-high speed processing (0.08 microseconds/step) and a software platform that allows users to create their own fully-customized code libraries, specific to their own needs. Up to 128 I/O points (analog and discrete) can be applied at a cost-per-point that wins new business for your business.

With a price/performance ratio that few competitors can even approach, the FP0R series lets designers and engineers strike exactly the right balance between machine performance and bottom line cost.

The FP0R’s built-in USB port programming interface eliminates the need for specialized serial cables (although the legacy RS-232 programming port is retained for backwards compatibility).

FP0H series PLCs

In late 2018, Panasonic introduced its evolution of the FP0R series in the form of the new FP0H. With the added capability and flexibility of dual Ethernet connections, the new series of controllers adds extremely modern and high end features at an impressive price point:

- Incredibly high-speed operation processing [8x faster than conventional models]

- High program storage capacity (up to 64k steps) [2x larger than conventional models]

- Data capacity: 12k / 24k / 32k / 64k Step variable

- Up to 384 I/O points and I/O modules from FP0H / FPΣ / FP0R series units can be added

- EtherNet/IP and Modbus-TCP protocol compatibility is built in

- Communications cassette system reduces unit cost and installation space

- An SD memory card slot and a logging trace function are provided

- FTP server and FTP client functions are available for remote SD card access

- A project copy function can copy ladder data without a PC (using only SD card)

- Maximum program capacity: 64k steps

- Motion control: control four axes simultaneously with pulse output (up to 100kHz per axis)

- The positioning unit (fast start-up in 5μs) can support ultra-fast linear servos

- The supported positioning unit RTEX can control Panasonic motors

- Ultra-compact size inherited from FPΣ series

- Ladder programs and motion libraries for FPΣ can be converted for FP0H

As with the FP0R series, the FP0H’s built-in USB port programming interface eliminates the need for specialized serial cables (although a legacy RS-232 programming port is retained for backwards compatibility).

FP-Sigma series PLCs

For applications where a higher degree of performance is needed, the FP-Sigma series from Panasonic is the answer.

By combining performance that rivals the fastest PLCs in the market with up to 32-discrete input/output points in a very small package, the FP-Sigma PLC units provide more memory, faster response, and easier programming/configuration than many competitors costing several times as much. The FP-Sigma platform is designed to be expanded using not only high-performance Sigma modules (motion control, communications, etc.) but also up to three I/O modules from the value-priced FP0R series on the same chassis.

FP-X series PLCs

With full-sized, removable terminal blocks, wiring time is greatly reduced when OEMs standardize on Panasonic’s FP-X series. With units carrying up to 60 discrete I/O points, the FP-X series can monitor and control machines in any industry.

Plus, when your application demands both value and a greater variety of input types, Panasonic’s unique set of Add-On Cassettes can be installed into the Expansion port(s) located on the face of each of the FP-X series controllers.

FP-X Add-On cassettes expand functionality to include analog I/O, high-speed pulse I/O, temperature control, memory, and six different communications options.

FP7 series PLCs

Featuring all the capabilities of PAC-grade controllers costing thousands of dollars more, the new FP7 series from Panasonic enhances machine control functions with advanced data collection and built-in web server capabilities.

The FP7 series is Ethernet/IP compatible across all Ethernet-enabled models. It includes a cassette architecture to expand functionality with additional I/O, communications, and data capabilities while keeping costs in check.

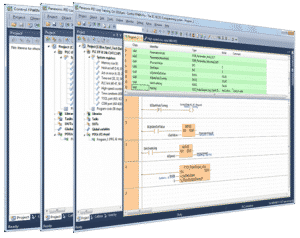

FP-Win Pro 7 PLC Programming Software (IEC 61131 compliant)

One of the most crucial factors every OEM must understand when selecting an automation platform is the software. The right (or wrong) software can make the difference between an automation platform that is scalable and maintainable and one that simply isn’t.

Panasonic’s FP-Win Pro 7 Software for PLCs is the all-in-one solution to program their entire PLC product set. With hundreds of built-in programming functions, full IEC-61131 compliance (including ladder logic, function block, structured text, and SFC), password protection, ability to create your own libraries, and much more, OEMs around the world know they can rely on FP-Win Pro to get their equipment up and running efficiently and inexpensively.

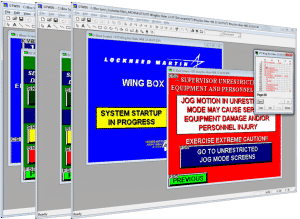

GT-series Touchscreen HMIs

With versions suitable for both indoor or outdoor applications, Panasonic’s GT series of touchscreens allow users to interface to many brands of popular machine controllers. With sizes ranging from 3.5″ to our largest 7″ widescreen format, every machine type with a need receive input from a human or provide machine information to a human is supported.

- The GT707 series offers a widescreen 7″ diagonal display in nearly the same panel cutout size as our previous generation GT32 models at 5.7″ size

- The GT32 series includes color and monochrome, indoor and outdoor, and communication options across many platforms

- By offering sixteen different versions, the GT12 series provides a range of options for machine builders looking for a compact, monochrome interface at an impressive value. GT12’s white/pink/red or green/orange/red color versions along with a screen that can be mounted in portrait or landscape orientation, represent an ideal option for machine interfacing.

- With the GT05 series, engineers can select between color or black and white versions giving ample functional screen real estate while consuming an unusually small overall footprint.

- The GT03-E represents the industry’s smallest chassis for a 3.5″ touchscreen on the market. Available with both monochrome and color options and with a mounting depth of only 30mm into the panel, the GT03-E is trusted by OEMs worldwide.

GT-Win Touchscreen Programming Software

Panasonic’s GT-WIN Ver. 3 software for touchscreens gives OEMs access to a built-in library of graphical operators (symbols for indicators, buttons, field equipment, and much more), animation controls for moving graphics, advanced text handling, and powerful datalogging tools. With one programming platform supporting the entire Panasonic GT-series of touchscreen products, GT-WIN represents the most efficient way to manage user interface consistency across all the equipment you build.