For nearly 25 years, Bihl+Wiedemann has set itself apart as a global leader in AS-i fieldbus I/O, and years in more recent years has emerged as a leader in AS-i Safety at Work technology. B+W’s history as one of the original innovators of the AS-i solution itself has helped them maintain a consistently high level of respect among the world’s most advanced automation solutions providers.

AS-Interface (Actuator Sensor Interface, AS-i) is an industrial fieldbus solution used in modern automation systems. It is designed for connecting binary ON/OFF field I/O devices (such devices typically include limit switches, actuators, sensors, rotary encoders, push buttons, valve position sensors, and more) in discrete manufacturing and process applications using a unique 2-conductor cable with a rectangular profile. AS-i’s innovative single-cable solution for both power and data provides inherent advantages to automation companies through immediate reductions in both up-front installation costs as well as long term maintenance and system expansion.

AS-Interface is an ‘open’ technology supported by a multitude of automation equipment vendors. According to AS-International Association there are currently (2018) over 25 million AS-Interface field devices installed globally, increasing at a rate of about 2 million devices per year.

AS-Interface, typically known as AS-i, is an incredibly flexible fieldbus solution. With AS-i gateways from Bihl+Wiedemann, users transmit digital and analog data which have been read remotely through AS-i slaves up to the host controller and set the output signals from the host controller to field-mounted actuators. Control commands for all actions originate within the control system’s protocol and are transferred to AS-i by intelligent Master/Gateway solutions.

AS-i SAFETY AT WORK was a natural evolution of the original AS-i fieldbus. As the safety of industrial systems grew more advanced, AS-i SAFE was developed to keep up with the higher level requirements of modern technology.

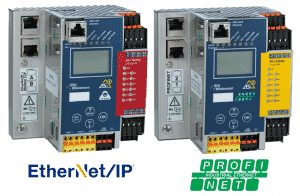

The heart of any AS-i connected fieldbus system is the Master or Gateway. This device lives between the overall control system and AS-i enabled field devices or standard field devices connected via AS-i modules. The Master controls AS-i traffic as it reports the status of field-installed sensors to the control system and transfers command signals from the control system

to activate actuators connected via AS-i slave modules.

There are many advantages to using B+W products in safety applications. First, we have the right products for any system size. In addition, these products provide functions that enable Safe Link between AS-i networks and optimal linking to the controller regardless of which fieldbus system is used.

For distributed systems of all types, B+W offers dozens of active and passive AS-i module types. Combining many options of input and/or output quantities, different cable connection types, and power options, B+W field modules form the nervous system of AS-i fieldbus systems installed worldwide.

The EXTREME Product Line modules from Bihl+Wiedemann are built for use under extreme conditions. The combination of IP67 protection rating and the AS-i standard enables reliable and efficient communication between machines.ngineering resources have always been stretched and that fact is more true today than ever.

- 100% protection against moisture

- Highest resistance to salt spray

- High corrosion resistance

- Benefits of the EXTREME Product Line

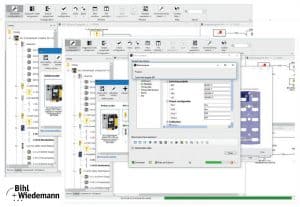

A great deal of B+W’s AS-i expertise is applied to providing customers with the best possible configuration software for AS-i Masters and Safety Monitors.

— AS-i Control Tools is the software of choice to clearly organize all important test and configuration options for AS-i networks.

— ASIMON360 is the right configuration software for AS-i Safety at Work.

With these advanced software solutions, you can easily design standard AS-i and AS-i Safe configurations directly on the computer with multi-window interfaces.

B+W software for diagnostics, service and approval measurements can be operated intuitively and allow PC-assisted measurement using existing hardware (Bihl+Wiedemann AS-i Master and connection cable). It assists the machine/systems builder in performing approval measurement and prophylactic troubleshooting. It also assists the end user in executing preventive maintenance as well as a fast and independent fault elimination.

Additionally, analysis data can be sent to our technical support allowing our technicians to provide fast and reliable assistance.